Advantages of using cable trays instead of conduit

In plant retrofit and expansion projects, it’s not just a matter of saving on capital equipment and labor costs, but also getting the job done quicker so the plant can get back to full productivity.

In many installations, one way to achieve these goals is to use armored, metal-clad and other permitted cable types installed in cable trays wherever practical. While the initial cost of the cable may be higher than non-armored cables protected by conduit, the labor time and cost of a cable tray installation can be much lower. That’s because working with conduit and pulling wires is extremely labor-intensive. And in hazardous locations, there’s also the work of installing and inspecting sealing fittings.

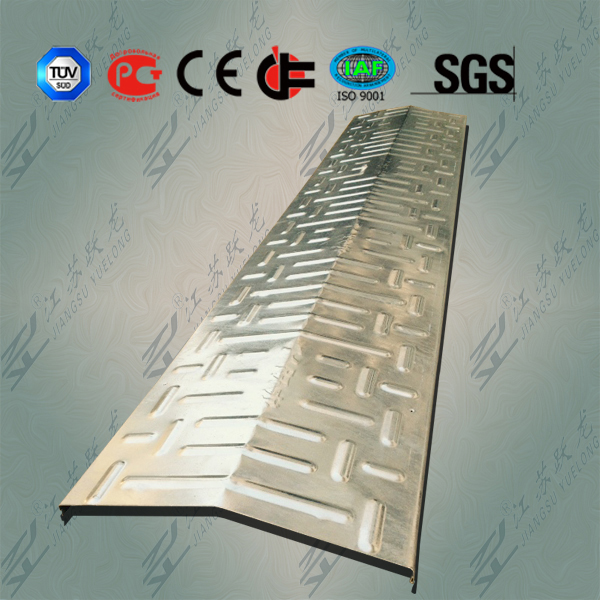

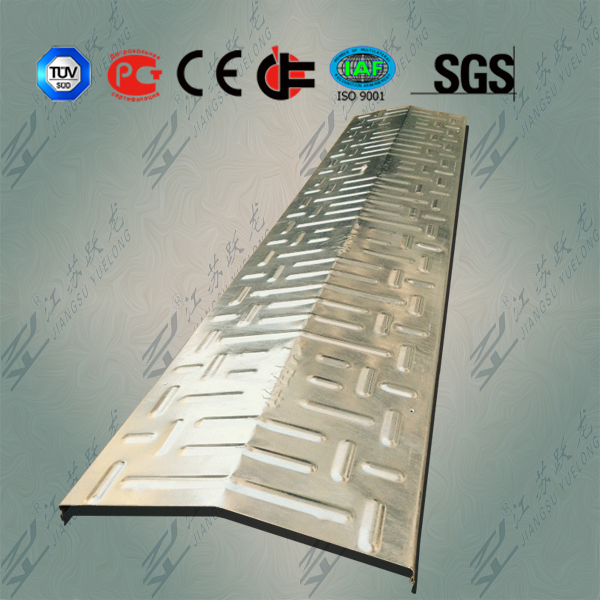

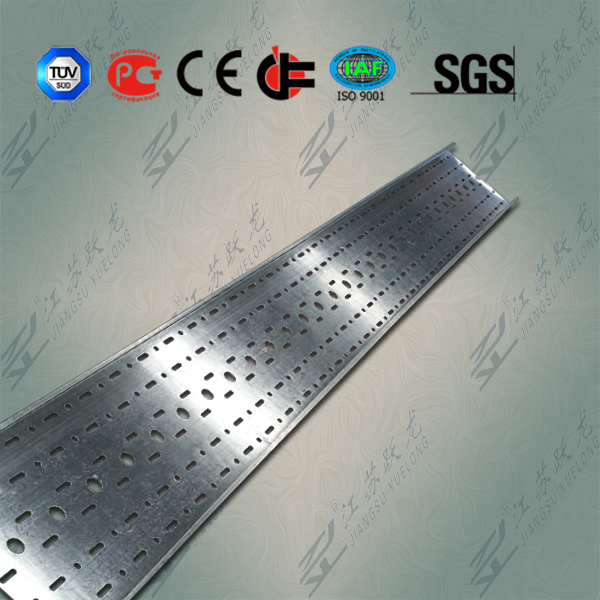

Many types of cable trays are commercially available. The most commonly used is the “ladder” type, which provides excellent ventilation and drainage, and is affordable and easy to work with. Other styles are available to accommodate specific needs – such as a solid-bottom design to support heavy cables. Since cable trays are intended to support the cable, not protect it, they should only be used with the wiring methods and procedures detailed in NEC Article 392. It’s also important to check with AHJs for any local regulations, such as a requirement that conduit be used for home runs to a main panel.

So why choose cable trays over conduit when reconfiguring or expanding a facility? Here are just a few reasons:

1) Faster installation. Installing cable tray is far less labor-intensive than conduit, so you get the job done faster and get the plant back to production sooner.

2) Easier training. Learning to measure, cut, bend, thread and seal conduit is difficult, and mastering it takes time and experience. Workers can gain proficiency with armored cables, cable glands and cable trays much more quickly.

3) Easier maintenance. When properly installed, cable trays and cables are easier to inspect and cost less to maintain.

4) Greater flexibility. If you already have conduit in place and simply want to change the wiring in it, there’s no reason to replace the conduit with cable trays. However, if you’re moving equipment – or might do so in the future – cable trays adapt easily to your requirements. You’re limited as to the number of wires or cables you can install in either system, but you’re far less limited with a cable tray due to the improved ventilation, and it’s much easier to install multiple trays than multiple conduits.

5) International consistency. For global companies, one of the best ways to improve operational efficiency is to establish consistent methods across their facilities. Using cable trays in both new and expanded or reconfigured facilities provides a perfect opportunity for standardization.

All of these points share one thing in common: Savings. That’s why, with budgets tightening and competition increasing, cable trays can help make new projects and retrofits more profitable, today and tomorrow.

Information about

recommended product

Hot Sale

Top articles

- Cable tray installment

- Cable tray selection

- How to see the cable tray layout whether qualified

- Non-metallic cable tray

- Cable tray market capacity is big

- Advantages of using cable trays instead of conduit

- Choosing right cable tray

- Cable trays adapt to changing needs

- How to choose cable tray

- Cable tray type selection