Choosing right cable tray

Cable carrier facility used to consider the following details to facilitate economical and efficient to make a montage.

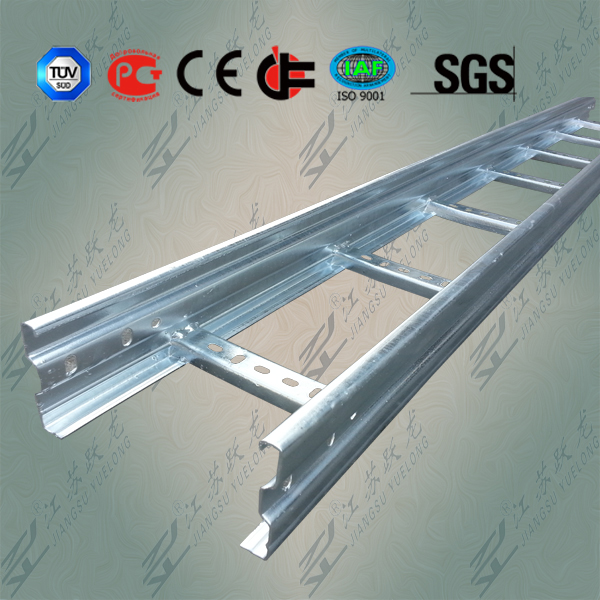

- Ladder Type (M) between the applications and support er?ti?i higher temperatures can be kept longer if used. However, stairs between the distance of the true must be appointed.

- Outdoor Type (F) Generally applied heat of the communication or a simple power transmission, such as at least in the case and outside the field application protection features increase their purposes.

- Canals (TR), a small amount of communication and power cables kullanylaca?? cases.

- Phone Type (W) are located inside the building for support in the short low-voltage, haberlebme and fiber optic cables are used for transporting.

1) Select a Type Carrier TEKOM catalog in one type of cable tray, cable attributes, different conditions for use of facilities such as convenience and aesthetic consideration some basic factors to select it. Types of carriers may be as follows:

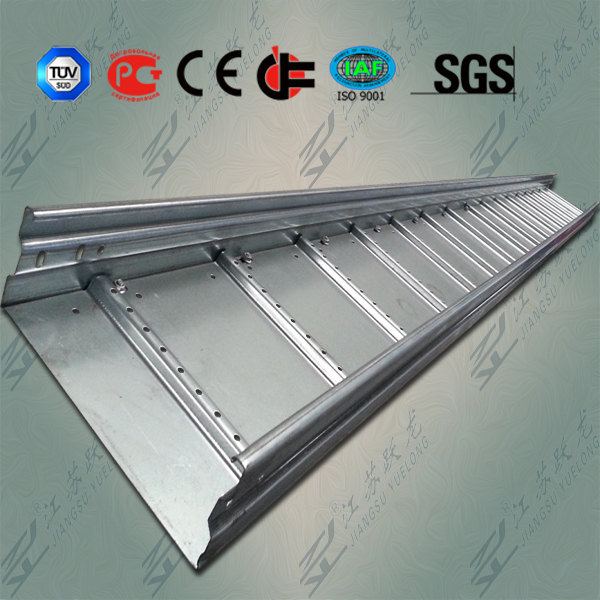

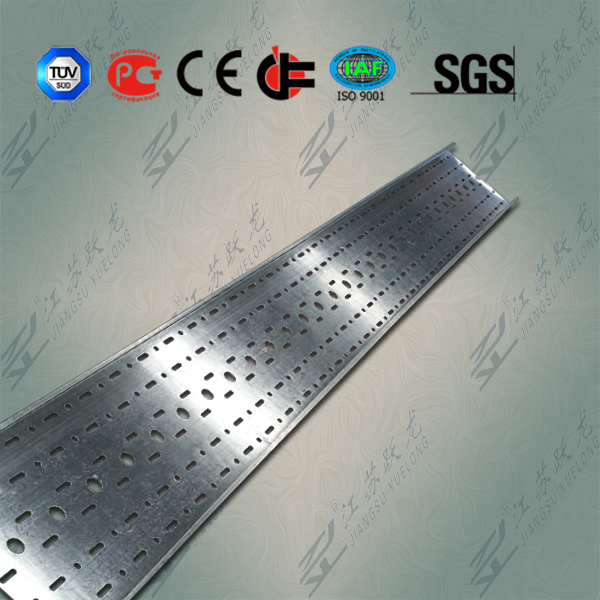

- Hole Type (D) through the hole in the base and sides allow enough of a haval?nd?rma. Applications does not exceed the average temperature is used in the field.

2) Select Material Type and Coating Types (For further information. What is Corrosion?) Cable carriers to use the atmospheric environment, a choice must be made as appropriate. But above all cable coating çepidi not conform to the types of carriers.

- Hot Dip Galvanizing (Materials business after plating) (HG), the different weather conditions, excellent protection against sa?lad??ndan more foreign media to be done in practice is preferred.

- Pregalvaniz (PG) in indoor applications is preferred.

- Stainless Steel (SS) corrosion resistance to many high with an expensive choice, especially the food industry and petrochemical industries are used. – Plastic Coating (Pl), black material on the plastic coating protection provided is.

- Dye (B) These electrostatic powder coating, single layer coating or traditional painting techniques derived from are the types of coatings.

3) Load Carrying Capacity of the materials according to the selection of proper thickness and height to determine the edge of the carrier is determined by considering the distance between the support cable trays should be installed to move the meter.

4) Edge Height Determination TEKOM Catalog different bearer types for different edge heights are specified (eg 40.48, 60, 75.100, 150). Carrier of the move to meters per load in accordance with standard cable carriers right side elevation to be determined.

- Cable laying will route prior determination (For this purpose machinery and equipment is the exact location and building structure of knowledge is required).

- Possible requirements also keeping in mind for each meter to the total cable hoist determination.

- Desired cable load to carry cable tray width and height of the supported distance between the detection. above Choosing the correct cable carrier for substances is inevitable. Below we provide you a roadmap to accomplish this is simple.

5) Width Determination Catalog TEKOM different widths are specified for different types of carriers. Accurate and efficient as in the picture below the minimum width should be determined with a cable management, if necessary, should be taken into consideration in the possible requirements and selection must be made with the accessories needed.

6) Radius of fittings to be used to determine the minimum allowable radius of the cable according to the radius of the fasteners should be identified.

Information about

- Cable tray installment

- Cable tray selection

- How to see the cable tray layout whether qualified

- Non-metallic cable tray

- Cable tray market capacity is big

- Advantages of using cable trays instead of conduit

- Cable trays adapt to changing needs

- How to choose cable tray

- Cable tray type selection

- What is the function of ladder cable tray?

Hot Sale

Top articles

- Cable tray installment

- Cable tray selection

- How to see the cable tray layout whether qualified

- Non-metallic cable tray

- Cable tray market capacity is big

- Advantages of using cable trays instead of conduit

- Choosing right cable tray

- Cable trays adapt to changing needs

- How to choose cable tray

- Cable tray type selection

Latest articles

- How to choose cable tray

- What is the function of ladder cable tray?

- Cable tray installment

- Advantages of using cable trays instead of conduit

- The case of Saudi Arabia HCC

- Cable trays adapt to changing needs

- Cable tray selection

- The case of Qilian Mountains cement factory

- The case of Russia TAF

- The case of Lafarge in Dujiangyan