Non-metallic cable tray

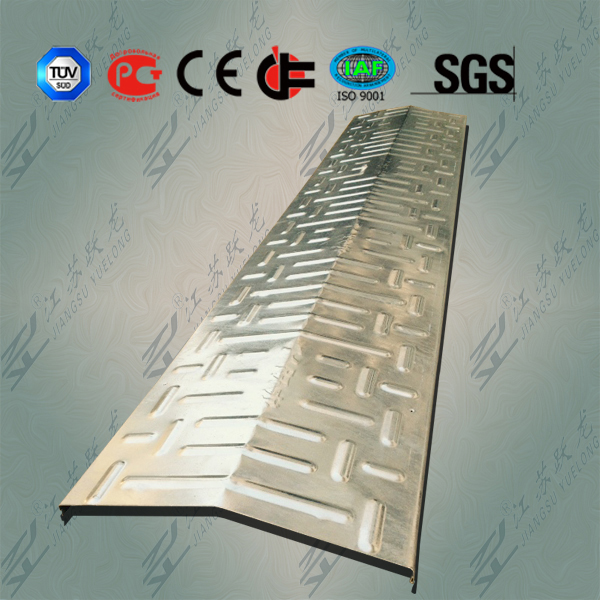

1. Hot dip galvanized. Under the condition of the atmosphere, zinc has good corrosion resistance. Galvanized as a sacrificial anode to protect cathode metal method. Its life depends on the galvanized layer thickness and the corrosion rate. Hot dip galvanized zinc layer thickness is in commonly 65 um (more than 455 g/m2). The combination of zinc and iron surface to form a layer of zinc iron alloy, enhanced the adhesion of the zinc layer. Overseas for various environmental conditions of hot dip galvanized layer atmospheric exposure tests have been carried out. From the experimental results, hot dip galvanized can meet the requirements of the service life of the cable tray.

Because of the hot dip galvanizing has good corrosion resistance and high performance and price, so steel hot dip galvanized steel bridge is widely used at home and abroad.

For thin wall and slenderness ratio larger components, easy to produce the problem such as deformation when hot dip galvanized, and galvanized cable tray structure is needed in the process into consideration.

2. Electric galvanized. Compared with electro galvanized and hot dip galvanized process is simple, the cost is low. No special requirements about the structure of cable tray. Electric galvanized after passivation treatment can significantly improve the protection performance. General electric galvanized layer around 12. And therefore is not suitable for life demand higher occasion.

Electric galvanized with ministerial standard of our country. For selection of electrodeposited coating, coating thickness, coating adhesion strength, resistance to corrosion test, etc all have specific provision, the selection of standard object is different, the content requirements also have differences. Manufacturer of electric galvanized bridge in our country at present is more, in reference to the relevant technical standards is not the same.

In order to improve the corrosion resistance of galvanized, electric galvanized iron nickel alloy or galvanized after can be used for high passivation (products such as "bridge" galvanized).

3. Electrostatic spraying. Spraying materials generally for PVC powder, polymer powder or anticorrosive powder. At the end of the Coating thickness at around 100. Electrostatic spraying has beautiful appearance, chemical corrosion prevention performance good characteristic. But low compared with the metal coating adhesion strength, resistance to erosion and particle wear ability is poor. Are deteriorating problem in use process, easy to cause local peeling coating, which makes the steel substrate corrosion, lead to coating large bubble peeling off. And the coating of uv resistance is poor, not suitable for outdoor use, modern bridge factory production such as: electrostatic spraying of cable tray.

4. Apply the antirust paint. For structure size larger components, due to the zinc pot, plating tank, oven and so on, generally can only adopt the method of coating anticorrosive paint to deal with. Although it has many characteristics, such as low cost, easy to use; But the anti-corrosion ability is poor. Short service life, maintenance workload is big, should not be commonly used.

5. Made by aluminum alloy bridge, has already been applied abroad. Both coastal salty area or high humidity and containing sulfur dioxide gas area. Cable tray made of aluminum alloy material, USES the natural exposure, the test results show that the ratio of steel cable tray has a significantly superior corrosion resistance, especially for aluminum alloy using its anti-corrosion effect is better after anodic oxidation, modern products such as: aluminum alloy cable tray.

5. Non-metallic cable tray, referred to as the norm. This new type of cable tray is made flame retardant synthetic resin as adhesive, glass fiber as reinforced material. It has high corrosion resistance, electric insulation performance, light in weight and has high strength, flame retardancy, colour and lustre is bright beautiful, use excellent features such as reliable. Apply to chemical industry, mine, salt fog corrosion area. Using glass fiber reinforced plastic cable tray, not only can save a lot of steel, also can save a lot of maintenance funds, reduce the labor intensity, prolong the service life of the cable.

Information about

- Cable tray installment

- Cable tray selection

- How to see the cable tray layout whether qualified

- Cable tray market capacity is big

- Advantages of using cable trays instead of conduit

- Choosing right cable tray

- Cable trays adapt to changing needs

- How to choose cable tray

- Cable tray type selection

- What is the function of ladder cable tray?

Hot Sale

Top articles

- Cable tray installment

- Cable tray selection

- How to see the cable tray layout whether qualified

- Non-metallic cable tray

- Cable tray market capacity is big

- Advantages of using cable trays instead of conduit

- Choosing right cable tray

- Cable trays adapt to changing needs

- How to choose cable tray

- Cable tray type selection

Latest articles

- The case of Russia TAF

- The case of Lafarge group

- How to see the cable tray layout whether qualified

- What is cable tray?

- Cable trays adapt to changing needs

- Cable tray selection

- Advantages of using cable trays instead of conduit

- Cable tray market capacity is big

- Choosing right cable tray

- The case of Lafarge in Dujiangyan